Advancements in Passivation and Metallization Techniques for n-Type Monocrystalline Silicon Solar Cells

DOI:

https://doi.org/10.51646/jsesd.v13i2.185Keywords:

N-type silicon solar cells, passivation, metallisation, efficiency, cost, industrialisation.Abstract

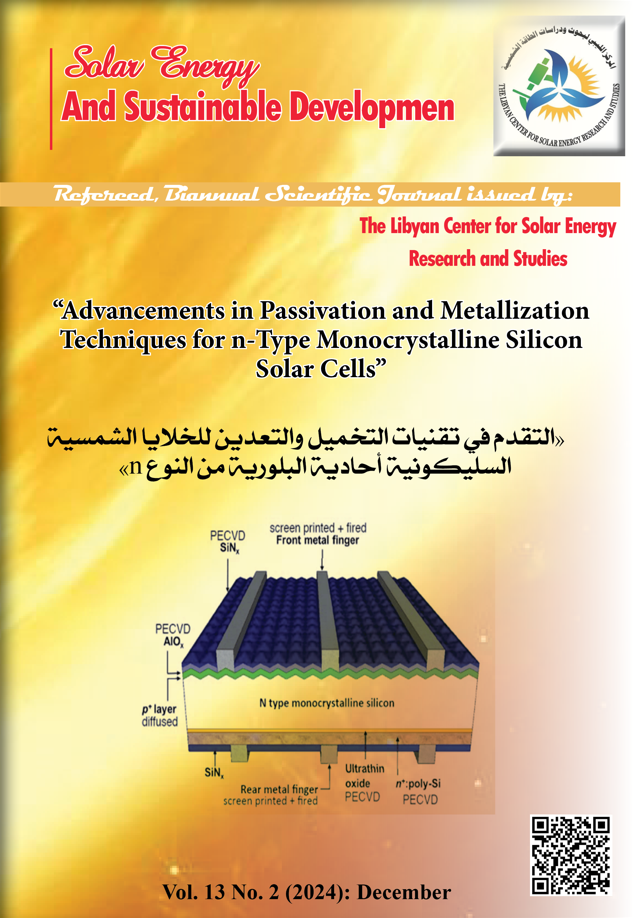

Crystalline n-type silicon (n-Si) solar cells are emerging as promising candidates to overcome the efficiency limitations of current p-type technologies, such as PERC cells. This article explores recent advances in passivation and metallisation techniques for monocrystalline n-Si solar cells, focusing on their impact on improving conversion efficiency and reducing manufacturing costs. The paper begins with a discussion of the importance of base material quality for n-Si cells. The impact of metallic impurities, oxide precipitates and thermal donors on minority carrier lifetime is analysed, as well as n-type silicon purification and passivation strategies, such as gettering. Next, the paper explores different contact passivation technologies, including silicon heterojunctions (SHJs), poly-Si and tunnel oxide TOPCon/POLO contacts, and metal oxide and organic compound contacts. The performance, advantages and manufacturing challenges of each technology are compared and discussed. Metallization techniques such as silver screen printing and more cost-effective and sustainable alternatives such as screen printing and copper plating are also examined. The impact of plating technologies on the performance of bifacial cells is also discussed. The paper then looks at n-Si bifacial solar cells and their potential to increase the energy efficiency of PV systems. Different bifacial cell concepts and their performance under real-world conditions are discussed, as well as the challenges and opportunities for their future development. Silicon-based tandem and multifunction solar cells are presented as a promising way to overcome the efficiency limits of single-junction cells. Perovskite-silicon tandems and III-V/silicon tandems, with their respective advantages and challenges, are examined in detail. Finally, the article discusses the economic and environmental aspects of n-type PV technologies, including cost of ownership (COO), discounted cost of energy (LCOE) and life cycle assessment (LCA). The importance of improving efficiency and reducing material use for the economic viability and sustainability of n-Si solar cells is highlighted. In conclusion, the paper highlights the crucial role of n-Si solar cells for the energy transition and highlights the opportunities and challenges for their development and large-scale deployment in the future.

Downloads

Metrics

References

M. Fischer, A. Gerlach, and H. Q. C. Gmbh, “State-of-the-art c-Si cell manufacturing : Trends in materials , processes and products identified in the 5th edition of the ITRPV roadmap,” vol. 2013, 2013.

A. Richter et al., “Design rules for high-efficiency both-sides-contacted silicon solar cells with balanced charge carrier transport and recombination losses,” Nat. Energy, vol. 6, no. 4, pp. 429–438, 2021, doi: 10.1038/s41560-021-00805-w. DOI: https://doi.org/10.1038/s41560-021-00805-w

D. Macdonald and L. J. Geerligs, “Recombination activity of interstitial iron and other transition metal point defects in p- and n-type crystalline silicon,” Appl. Phys. Lett., vol. 85, no. 18, pp. 4061–4063, 2004, doi: 10.1063/1.1812833. DOI: https://doi.org/10.1063/1.1812833

J. S. and K. Bothe, “Structure and transformation of the metastable boron- and oxygen-related defect center in crystalline silicon,” Phys. Rev. B 69, 024107 – Publ. 22 January 2004. DOI: https://doi.org/10.1103/PhysRevB.69.024107

C. Gerardi, “A European sustainable champion in PV manufacturing industry,” 2022.

M. Taguchi, K. Kawamoto, S. Tsuge, T. Baba, and H. Sakata, “Cells*High! Ef_ciency Crystalline Si Cells with Novel Structure,” Mater. Res., vol. 8, no. January, pp. 503–513, 2000. DOI: https://doi.org/10.1002/1099-159X(200009/10)8:5<503::AID-PIP347>3.0.CO;2-G

Y. Tao, V. Upadhyaya, K. Jones, and A. Rohatgi, “Tunnel oxide passivated rear contact for large area n-type front junction silicon solar cells providing excellent carrier selectivity,” AIMS Mater. Sci., vol. 3, no. 1, pp. 180–189, 2016, doi: 10.3934/matersci.2016.1.180. DOI: https://doi.org/10.3934/matersci.2016.1.180

G. M. A. . D. E. S. G. Y. M. K. N. B. K. H. Xiaojing, “Solar cell efficiency tables (Version 61),” JRC Publ. Repos., doi: 10.1002/pip.3646 (online). DOI: https://doi.org/10.1002/pip.3646

R. Kopecek and J. Libal, “Bifacial photovoltaics 2021: Status, opportunities and challenges,” Energies, vol. 14, no. 8, 2021, doi: 10.3390/en14082076. DOI: https://doi.org/10.3390/en14082076

“B. Ceccaroli, E. Ovrelid, and S. Pizzini (Eds.), Solar Silicon Processes: Technologies, Challenges, and Opportunities, Boca Raton, FL: CRC Press, 2016, doi:10.1201/9781315369075.”. DOI: https://doi.org/10.1201/9781315369075

“Aberle, A.G., ‘Crystalline silicon solar cells: Advanced surface passivation and analysis’, Centre for Sustainable Energy Systems, Australian National University, 2000.”.

I. E. T. Energy and E. Series, n-Type Crystalline Silicon Photovoltaics.

J. Schmidt et al., “Impurity-related limitations of next-generation industrial silicon solar cells,” IEEE J. Photovoltaics, vol. 3, no. 1, pp. 114–118, 2013, doi: 10.1109/JPHOTOV.2012.2210030. DOI: https://doi.org/10.1109/JPHOTOV.2012.2210030

J. D. Murphy, M. Al-Amin, K. Bothe, M. Olmo, V. V. Voronkov, and R. J. Falster, “The effect of oxide precipitates on minority carrier lifetime in n -type silicon,” J. Appl. Phys., vol. 118, no. 21, 2015, doi: 10.1063/1.4936852. DOI: https://doi.org/10.1063/1.4936852

M. Tomassini et al., “Recombination activity associated with thermal donor generation in monocrystalline silicon and effect on the conversion efficiency of heterojunction solar cells,” J. Appl. Phys., vol. 119, no. 8, 2016, doi: 10.1063/1.4942212. DOI: https://doi.org/10.1063/1.4942212

R. A. Sinton, A. Cuevas, and R. A. Sinton, “Contactless determination of current – voltage characteristics and minority-carrier lifetimes in semiconductors from quasi-steady-state photoconductance data Contactless determination of current – voltage characteristics and minority- carrier lifetimes in,” vol. 2510, no. 1996, pp. 1–4, 2015, doi: 10.1063/1.117723. DOI: https://doi.org/10.1063/1.117723

T. Trupke, R. A. Bardos, M. C. Schubert, and W. Warta, “Photoluminescence imaging of silicon wafers,” Appl. Phys. Lett., vol. 89, no. 4, pp. 87–90, 2006, doi: 10.1063/1.2234747. DOI: https://doi.org/10.1063/1.2234747

“Seibt, M., ‘High-resolution transmission electron microscopy of extended defects in semiconductors’, Materials Science and Engineering: R: Reports, 2002. 36(1-6): p. 59-144.”.

O. De Gryse, P. Clauws, L. Rossou, J. Van Landuyt, and J. Vanhellemont, “Accurate infrared spectroscopy determination of interstitial and precipitated oxygen in highly doped Czochralski-grown silicon,” Rev. Sci. Instrum., vol. 70, no. 9, pp. 3661–3663, 1999, doi: 10.1063/1.1149974. DOI: https://doi.org/10.1063/1.1149974

M. Seibt, A. Sattler, C. Rudolf, O. Voß, V. Kveder, and W. Schröter, “Gettering in silicon photovoltaics: Current state and future perspectives,” Phys. Status Solidi Appl. Mater. Sci., vol. 203, no. 4, pp. 696–713, 2006, doi: 10.1002/pssa.200664516. DOI: https://doi.org/10.1002/pssa.200664516

A. Haarahiltunen, H. Savin, M. Yli-Koski, H. Talvitie, and J. Sinkkonen, “Modeling phosphorus diffusion gettering of iron in single crystal silicon,” J. Appl. Phys., vol. 105, no. 2, 2009, doi: 10.1063/1.3068337. DOI: https://doi.org/10.1063/1.3068337

V. Vähänissi, A. Haarahiltunen, M. Yli-Koski, and H. Savin, “Gettering of iron in silicon solar cells with implanted emitters,” IEEE J. Photovoltaics, vol. 4, no. 1, pp. 142–147, 2014, doi: 10.1109/JPHOTOV.2013.2285961. DOI: https://doi.org/10.1109/JPHOTOV.2013.2285961

A. Y. Liu, C. Sun, V. P. Markevich, A. R. Peaker, J. D. Murphy, and D. Macdonald, “Gettering of interstitial iron in silicon by plasma-enhanced chemical vapour deposited silicon nitride films,” J. Appl. Phys., vol. 120, no. 19, 2016, doi: 10.1063/1.4967914. DOI: https://doi.org/10.1063/1.4967914

A. G. Aberle and University of New South Wales. Centre for Photovoltaic Engineering., “Crystalline silicon solar cells : advanced surface passivation and analysis,” p. 335, 1999.

S. Gupta, “Theoretical characterization of point defects in semiconductors : from photovoltaics to quantum engineering applications Sameer Gupta To cite this version : HAL Id : tel-04166887 conducteurs : du photovoltaïque aux applications d ’ ingénierie quantique Th,” 2023.

L. Korte and M. Schmidt, “Doping type and thickness dependence of band offsets at the amorphous/crystalline silicon heterojunction,” J. Appl. Phys., vol. 109, no. 6, 2011, doi: 10.1063/1.3559296. DOI: https://doi.org/10.1063/1.3559296

M. A. Green et al., “Solar cell efficiency tables (Version 61),” Prog. Photovoltaics Res. Appl., vol. 31, no. 1, pp. 3–16, 2023, doi: 10.1002/pip.3646. DOI: https://doi.org/10.1002/pip.808

H. Steinkemper, F. Feldmann, M. Bivour, and M. Hermle, “Theoretical Investigation of Carrier-selective Contacts Featuring Tunnel Oxides by Means of Numerical Device Simulation,” Energy Procedia, vol. 77, pp. 195–201, 2015, doi: 10.1016/j.egypro.2015.07.027. DOI: https://doi.org/10.1016/j.egypro.2015.07.027

Y. Chen et al., “Mass production of industrial tunnel oxide passivated contacts (i-TOPCon) silicon solar cells with average efficiency over 23% and modules over 345 W,” Prog. Photovoltaics Res. Appl., vol. 27, no. 10, pp. 827–834, 2019, doi: 10.1002/pip.3180. DOI: https://doi.org/10.1002/pip.3180

J. Bullock et al., “Dopant-Free Partial Rear Contacts Enabling 23% Silicon Solar Cells,” Adv. Energy Mater., vol. 9, no. 9, pp. 1–6, 2019, doi: 10.1002/aenm.201803367. DOI: https://doi.org/10.1002/aenm.201803367

J. Geissbühler, A. Faes, A. Lachowicz, C. Ballif, M. Despeisse, and C. Pv-center, “”.

J. Dréon et al., “23.5%-Efficient Silicon Heterojunction Silicon Solar Cell Using Molybdenum Oxide As Hole-Selective Contact,” Nano Energy, vol. 70, no. October 2019, 2020, doi: 10.1016/j.nanoen.2020.104495. DOI: https://doi.org/10.1016/j.nanoen.2020.104495

R. H. G. MICHAEL J. SAILOR, ERIC J. GINSBURG, CHRISTOPHER B. GORMAN, AMIT KUMAR, “Thin Films of n-Si/Poly-(CH3)3Si-Cyclooctatetraene: Conducting-Polymer Solar Cells and Layered Structures,” vol. 63, no. 1989, 1990.

D. Zielke, C. Niehaves, W. Lövenich, A. Elschner, M. Hörteis, and J. Schmidt, “Organic-silicon Solar Cells Exceeding 20% Efficiency,” Energy Procedia, vol. 77, no. August 2020, pp. 331–339, 2015, doi: 10.1016/j.egypro.2015.07.047. DOI: https://doi.org/10.1016/j.egypro.2015.07.047

L. Tous, J. Govaerts, S. Harrison, A. E. Commission, C. Carriere, and A. E. Commission, “Overview of Key Results Achieved in H2020 HighLite Project Helping to Raise the EU PV Industries ’ Competitiveness,” no. March 2023, 2022. DOI: https://doi.org/10.1002/pip.3667

“ITRPV 2012, International Technology Roadmap for Photovoltaics Results 2012, Third Edition, Berlin 2012”.

“Tepner, S., Ney, L., Linse, M., Lorenz, A., Pospischil, M., and Clement, F. (2020). Studying knotless screen patterns for fine-line screen printing of Si_solar cells. IEEE Journal of Photovoltaics, 10(2), 319–325”. DOI: https://doi.org/10.1109/JPHOTOV.2019.2959939

ITRPV, “International Technology Roadmap for Photovoltaics ( ITRPV ) 8 th edition : Crystalline Silicon Technology ̶ Current Status and Outlook,” Work. ITRPV – VDMA Photovolt. Equip., pp. 1–40, 2017.

Y. Zhang, M. Kim, L. Wang, P. Verlinden, and B. Hallam, “Design considerations for multi-terawatt scale manufacturing of existing and future photovoltaic technologies: Challenges and opportunities related to silver, indium and bismuth consumption,” Energy Environ. Sci., vol. 14, no. 11, pp. 5587–5610, 2021, doi: 10.1039/d1ee01814k. DOI: https://doi.org/10.1039/D1EE01814K

C. Schmiga, B. Grübel, G. Cimiotti, and ..., “23.8% Efficient Bifacial i-TOPCon Silicon Solar Cells with< 20 µm Wide Ni/Cu/Ag-Plated Contact Fingers,” Met. …, 2021, [Online]. Available: https://miworkshop.info/wp-content/uploads/2021/11/4.4_Schmiga_F-ISE.pdf

R. Rosenberg, D. C. Edelstein, C. Hu, and K. P. Rodbell, “C Opper M Etallization F or H Igh,” Annu. Rev. Mater. Sci., vol. 30, no. November, pp. 229–262, 2000. DOI: https://doi.org/10.1146/annurev.matsci.30.1.229

D. Stüwe, D. Mager, D. Biro, and J. G. Korvink, “Inkjet technology for crystalline silicon photovoltaics,” Adv. Mater., vol. 27, no. 4, pp. 599–626, 2015, doi: 10.1002/adma.201403631. DOI: https://doi.org/10.1002/adma.201403631

J. Lossen, M. Matusovsky, A. Noy, C. Maier, and M. Bähr, “Pattern Transfer Printing (PTPTM) for c-Si Solar Cell Metallization,” Energy Procedia, vol. 67, no. May, pp. 156–162, 2015, doi: 10.1016/j.egypro.2015.03.299. DOI: https://doi.org/10.1016/j.egypro.2015.03.299

J. Libal and R. Kopecek, “Bifacial Photovoltaics: Technology, applications and economics,” Bifacial Photovoltaics Technol. Appl. Econ., pp. 1–330, Oct. 2018, doi: 10.1049/PBPO107E. DOI: https://doi.org/10.1049/PBPO107E

T. S. Liang et al., “A review of crystalline silicon bifacial photovoltaic performance characterisation and simulation,” Energy Environ. Sci., vol. 12, no. 1, pp. 116–148, 2019, doi: 10.1039/c8ee02184h. DOI: https://doi.org/10.1039/C8EE02184H

C. Luo et al., “Influence and characteristic of shading on photovoltaic performance of bifacial modules and method for estimating bifacial gain,” Build. Simul., vol. 16, no. 10, pp. 1821–1833, Oct. 2023, doi: 10.1007/S12273-022-0966-0/METRICS. DOI: https://doi.org/10.1007/s12273-022-0966-0

T. Dullweber et al., “PERC+: industrial PERC solar cells with rear Al grid enabling bifaciality and reduced Al paste consumption,” Prog. Photovoltaics Res. Appl., vol. 24, no. 12, pp. 1487–1498, Dec. 2016, doi: 10.1002/PIP.2712. DOI: https://doi.org/10.1002/pip.2712

“N-type TOPCon a Sign of the Time – pv magazine International.” https://www.pv-magazine.com/press-releases/n-type-topcon-a-sign-of-the-time/?fbclid=IwZXh0bgNhZW0CMTAAAR2aoxquaiEtrrsJBzXAdY51Eb9ZqPEljGNLlm-Jz5esYuNX2Jo6ieuQN9Q_aem_AYga0t1E8D_2oJ0IQTu8qHtPM6mv7vKx8TOoXRG5gPnJcqdEl3V9S8-037WPAvwzRbE6KERhvQzVM3DsiBntGj8g (accessed Apr. 20, 2024).

J. Haschke, O. Dupré, M. Boccard, and C. Ballif, “Silicon heterojunction solar cells: Recent technological development and practical aspects - from lab to industry,” Sol. Energy Mater. Sol. Cells, vol. 187, no. August, pp. 140–153, 2018, doi: 10.1016/j.solmat.2018.07.018. DOI: https://doi.org/10.1016/j.solmat.2018.07.018

“IEA Photovoltaic Power Systems (PVPS) - IEA Research Cooperation.” https://nachhaltigwirtschaften.at/en/iea/technologyprogrammes/pvps/ (accessed Apr. 20, 2024).

T. S. Liang, M. Pravettoni, J. P. Singh, and Y. S. Khoo, “Meeting the requirements of IEC TS 60904-1-2 for single light source bifacial photovoltaic characterisation: Evaluation of different back panel materials,” Eng. Res. Express, vol. 2, no. 1, 2020, doi: 10.1088/2631-8695/ab7ee5. DOI: https://doi.org/10.1088/2631-8695/ab7ee5

J. Lopez-Garcia et al., “Implementation of the IEC TS 60904-1-2 Measurement Methods for Bifacial Silicon PV Devices,” IEEE J. Photovoltaics, vol. 12, no. 3, pp. 787–797, 2022, doi: 10.1109/JPHOTOV.2022.3161186. DOI: https://doi.org/10.1109/JPHOTOV.2022.3161186

W. Shockley and H. J. Queisser, “Detailed balance limit of efficiency of p-n junction solar cells,” J. Appl. Phys., vol. 32, no. 3, pp. 510–519, 1961, doi: 10.1063/1.1736034. DOI: https://doi.org/10.1063/1.1736034

M. Ratner, “ The Physics of Solar Cells ; Third Generation Photovoltaics: Advanced Solar Energy Conversion ,” Phys. Today, vol. 57, no. 12, pp. 71–72, 2004, doi: 10.1063/1.1878345. DOI: https://doi.org/10.1063/1.1878345

“J. Hofstetter, D. P. Fenning, D. M. Powell, A. E. Morishige, H. Wagner, and T. Buonassisi, ‘Sorting metrics for customized phosphorus diffusion gettering,’ IEEE J. Photovolt., vol. 4, no. 6, pp. 1421–1428, 2014, doi:10.1109/JPHOTOV.2014.2349736.”. DOI: https://doi.org/10.1109/JPHOTOV.2014.2349736

“G. Coletti, I. Gordon, M. C. Schubert, et al., ‘Challenges for photovoltaic silicon materials,’ Sol. Energy Mater. Sol. Cells, vol. 130, pp. 629–633, Nov. 2014, doi:10.1016/j.solmat.2014.07.045.”. DOI: https://doi.org/10.1016/j.solmat.2014.07.045

M. A. Green, A. Ho-Baillie, and H. J. Snaith, “The emergence of perovskite solar cells,” Nat. Photonics, vol. 8, no. 7, pp. 506–514, 2014, doi: 10.1038/nphoton.2014.134. DOI: https://doi.org/10.1038/nphoton.2014.134

L. Mao et al., “Fully Textured, Production-Line Compatible Monolithic Perovskite/Silicon Tandem Solar Cells Approaching 29% Efficiency,” Adv. Mater., vol. 34, no. 40, pp. 1300–1309, 2022, doi: 10.1002/adma.202206193. DOI: https://doi.org/10.1002/adma.202206193

“EPFL and CSEM achieve 31.25% efficiency for tandem perovskite-silicon solar cell, https://www.pv-magazine.com/2022/07/07/csem-epfl-achieve-31-25-efficiency-for-tandem-perovskite-silicon-solar-cell/”.

S. Essig et al., “Raising the one-sun conversion efficiency of III-V/Si solar cells to 32.8% for two junctions and 35.9% for three junctions,” Nat. Energy, vol. 2, no. 9, 2017, doi: 10.1038/nenergy.2017.144. DOI: https://doi.org/10.1038/nenergy.2017.144

“Aydin E, Allen TG, De Bastiani M, et al. Interplay between temperature and bandgap energies on the outdoor performance of perovskite/silicon tandem solar cells. Nat Energy. 2020 Nov;5(11):851–9.”. DOI: https://doi.org/10.1038/s41560-020-00687-4

“Josˇt M, Lipovsˇek B, Glazˇar B, et al. Perovskite solar cells go outdoors: field testing and temperature effects on energy yield. Adv Energy Mater. 2020;10(25):2000454.”. DOI: https://doi.org/10.1002/aenm.202000454

“Mariotti S, Ja¨ger K, Diederich M, et al. Monolithic perovskite/silicon tan_dem solar cells fabricated using industrial p-type polycrystalline silicon on oxide/passivated emitter and rear cell silicon bottom cell technology. Sol RRL. 2022;n/a:2101066”. DOI: https://doi.org/10.1002/solr.202101066

Clean Energy Technology Observatory and European Commission, Photovoltaics in the European Union. 2022. doi: 10.2760/812610.

K. Branker, M. J. M. Pathak, and J. M. Pearce, “A review of solar photovoltaic levelized cost of electricity,” Renew. Sustain. Energy Rev., vol. 15, no. 9, pp. 4470–4482, 2011, doi: 10.1016/j.rser.2011.07.104. DOI: https://doi.org/10.1016/j.rser.2011.07.104

“International Organization for Standardization (ISO), ‘ISO 14040:2006 Environmental management - Life cycle assessment - Principles and framework’, 2006.”.

“Beaucarne G, Eder G, Jadot E, Voronko Y, and Mu¨hleisen W. Repair and preventive maintenance of photovoltaic modules with degrading backsheets using flowable silicone sealant. Prog. Photovolt. Res. Appl. 2022;30: 1045–1053.”. DOI: https://doi.org/10.1002/pip.3492

G. A. Heath, D. Ravikumar, B. Hansen, and E. Kupets, “A critical review of the circular economy for lithium-ion batteries and photovoltaic modules–status, challenges, and opportunities,” J. Air Waste Manag. Assoc., vol. 72, no. 6, pp. 478–539, 2022, doi: 10.1080/10962247.2022.2068878. DOI: https://doi.org/10.1080/10962247.2022.2068878

“Liu W, Zhang L, Yang X, et al. Damp-heat-stable, high-efficiency, industrial-size silicon heterojunction solar cells. Joule 2020;4:913–927. [19] https://www.firstsolar.com/-/media/First-Solar/Sustainability-Documents/ FirstSolar_Sustainability-Report_2021”. DOI: https://doi.org/10.1016/j.joule.2020.03.003

IEA, “Renewables 2022, Analysis and forecast to 2027,” Int. Energy Agency, p. 158, 2022, [Online]. Available: https://www.iea.org/reports/renewables-2022; License: CC BY 4.0

“International Technology Roadmap for Photovoltaic (ITRPV): R&D findings from the 13th Edition - Other news - ETIP PV.” https://etip-pv.eu/news/other-news/international-technology-roadmap-for-photovoltaic-itrpv-r-d-findings-from-the-13th-edition/ (accessed Apr. 21, 2024).

J. Geissbühler, A. Faes, A. Lachowicz, C. Ballif, and M. Despeisse, “Metallisation techniques and interconnection schemes for high-efficiency silicon heterojunction PV,” Photovoltaics Int., vol. 37, pp. 61–69, 2017, [Online]. Available: www.vonardenne.biz

H. Ziar, P. Manganiello, O. Isabella, and M. Zeman, “Photovoltatronics: Intelligent PV-based devices for energy and information applications,” Energy Environ. Sci., vol. 14, no. 1, pp. 106–126, 2021, doi: 10.1039/d0ee02491k. DOI: https://doi.org/10.1039/D0EE02491K

R. Contreras-Lisperguer, E. Muñoz-Cerón, J. Aguilera, and J. de la Casa, “A set of principles for applying Circular Economy to the PV industry: Modeling a closed-loop material cycle system for crystalline photovoltaic panels,” Sustain. Prod. Consum., vol. 28, pp. 164–179, 2021, doi: 10.1016/j.spc.2021.03.033. DOI: https://doi.org/10.1016/j.spc.2021.03.033

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Solar Energy and Sustainable Development Journal

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.